Unique Ingredients for Unprecedented Results: The Founders of RISE®

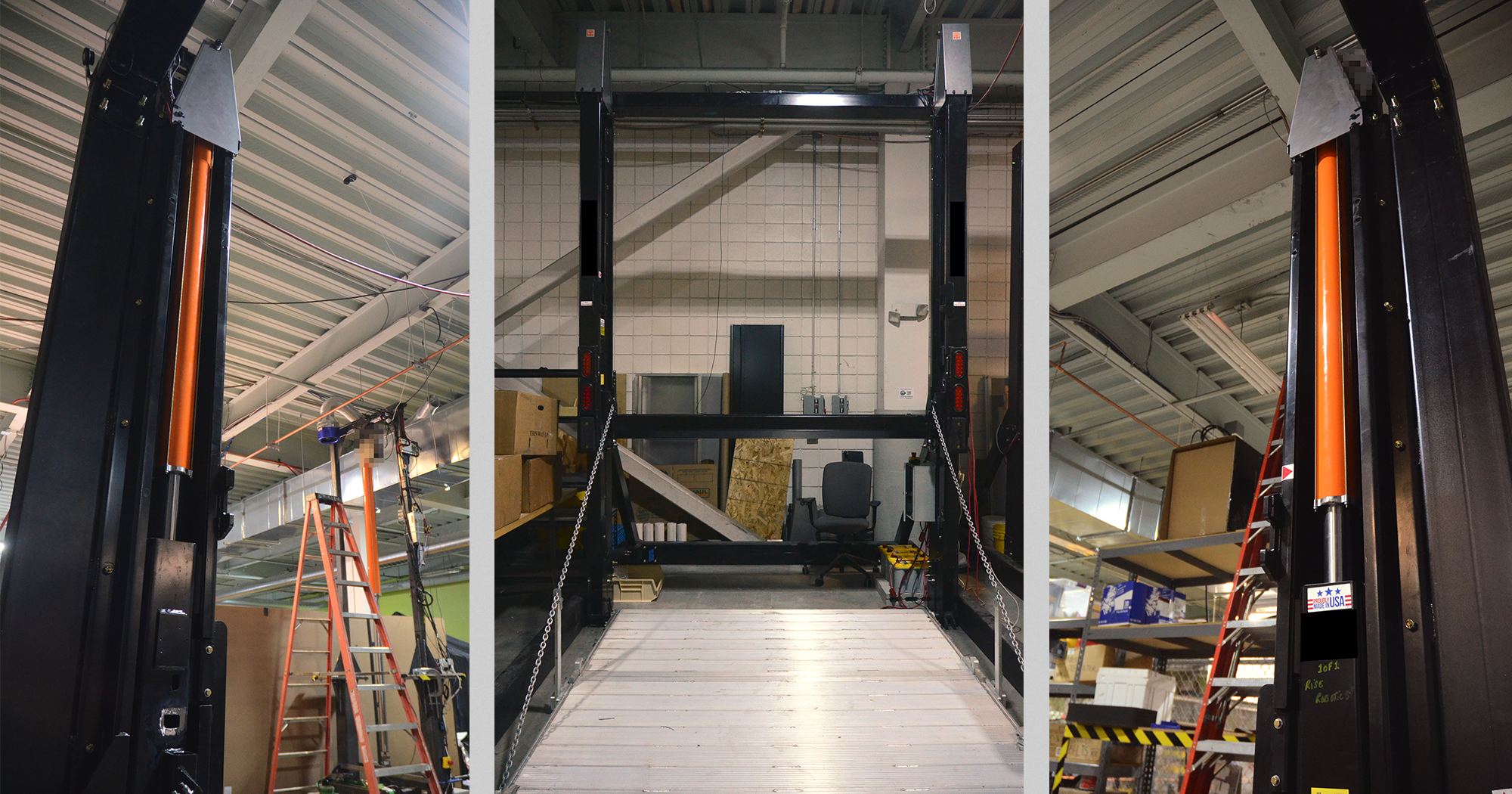

A decade following the company's conception by two ambitious, freshly graduated MIT engineers, RISE® and the cutting-edge technology of their design are making their major market debut. At last, they are partnering with Anthony Liftgates to present a liftgate more efficient, reliable, and sustainable than any before. Powered by RISE®Technology, the product provides the first large-scale demonstration of the new actuator's ability to offer a superior alternative to hydraulics and outperform them in critical ways; indeed, it is the world's first fully self-sustaining liftgate.

Offering an answer to the issue of high power consumption of liftgates, which are overburdening and often draining delivery truck batteries, RISE® is the first to provide a solution to one of the material handling industry's most widespread and longstanding issues. Simultaneously, they are advancing the sphere of hydraulic technology unlike any seen in decades. It may be surprising, then, to learn that its founders began as outsiders to the industry, pursuing an endeavor slightly removed from where their work has brought them today. Rather than starting with the goal of offering an alternative to hydraulics, the company began with a product in mind, of which actuation is the single most valuable component: an advanced exoskeleton that would enhance the range of human motion. It was this pursuit that allowed the team to produce the innovations that are now transforming the industry.

Each of RISE®'s four founders— Arron Acosta, Blake Sessions, Toomas Sepp, and Kyle Dell'Aquila— brought a unique perspective and a broad and diverse range of experience to the project skills and expertise. This combination allowed for new interpretations of actuation and heavy machinery and their mechanics and designs and gave the team all the capabilities needed to execute them. Arron and Blake provided the project's foundation with their ambition, passion, and talent, moving them to create the company and perform the tireless work of its first exploratory year. The later recruitment of each additional founder marked vital turning points in the progression of RISE® as we know it today. Toomas, who joined in year two, offered capabilities in conceptualization, design, and construction that allowed the team the freedom of prototyping and testing, which spurred the discovery of their novel power transmission methods. Later, Kyle's joining the team signaled their move towards making their new actuator a complete industrial product. The Rhode Island School of Design graduate helped them to visualize its applications and build awareness by communicating the story of RISE® and its unique concept. These turning points exemplify how each founder provided a necessary ingredient to the company's success and their product, continuously building upon each other to make real innovation a possibility.

The story of the belt dilemma, the point at which RISE® Technology went from a promising concept to an executable reality, aptly illustrates both how the team's unconventional origins helped them reach success and how each member fueled the endeavor in crucial ways by sharing knowledge and ideas, making observations, and offering their abilities. The tale begins with material testing on one of RISE®'s early designs, with the team trying the absolute limits of a high-performance material they had identified as a candidate for their design. Noticing some asymmetrical wear on the belt during testing, the team gathered to dissect the phenomenon, determine its cause, and devise its solution, Toomas setting to work checking the validity of their assumptions. In a somewhat whimsical twist, what finally triggered the breakthrough critical to their success was a casual, joking brainstorming session between Arron and Kyle, producing a seemingly absurd suggestion that eventually resulted in the groundbreaking advancement that would not only propel RISE®Technology forward but challenge some foundations of engineering. Blake then tapped into his biomechanical roots to take observation down to its most basic level.

Common wisdom surrounding belts states that there are two "sins" possible in their use, ways in which they are sure to degrade: twisting a belt or fleeting it. Although well aware of this convention, the founders were not bound by the framework of thought traditional engineers would have been— what many viewed as a sure stopping block they saw as a point of interest and possible opportunity. Here, RISE® did what no engineer had thought to do. Rather than scrap their concept entirely at the first instance of a twisted belt degrading, they pushed ahead to examine the results of their tests without assumptions, thoroughly, and at their most fundamental levels. Ultimately, the design that brought them success would be one flouting the rules of belts completely, both twisting and fleeting the belt to improve its durability tenfold.

With the world of industrial technology, RISE® is a company with an unconventional product and an even-more-so background. With no two members following the same trajectory to reach their place on the team, the team contained all the necessary components to achieve an unprecedented solution that is unlikely to have developed within the traditional environment. Today, the founders' contributions have found their place in a revolutionary technology that stands not only to offer an alternative to hydraulics but to make impressive, lasting changes in our environment and quality of life.