RISE™ Robotics is thrilled to announce the addition of Selma Svendsen to their esteemed team as the new Vice President of Engineering. With a remarkable track record in the tech industry spanning over two decades, Selma brings extensive expertise in engineering, global strategic sourcing, and new product introductions (NPI). Her remarkable achievements include managing multimillion-dollar budgets, transforming businesses, and assembling cross-functional teams that drive operational excellence.

Selma's outstanding contributions have earned her numerous accolades, including the prestigious "Best Invention" recognition by Time Magazine, the "Best of What's New" Popular Science award, and induction into the Women in Technology International Hall of Fame in 2017. These well-deserved honors bear testament to her innovative problem-solving skills and unwavering commitment to excellence.

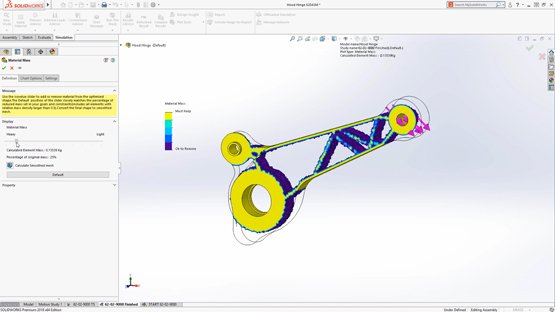

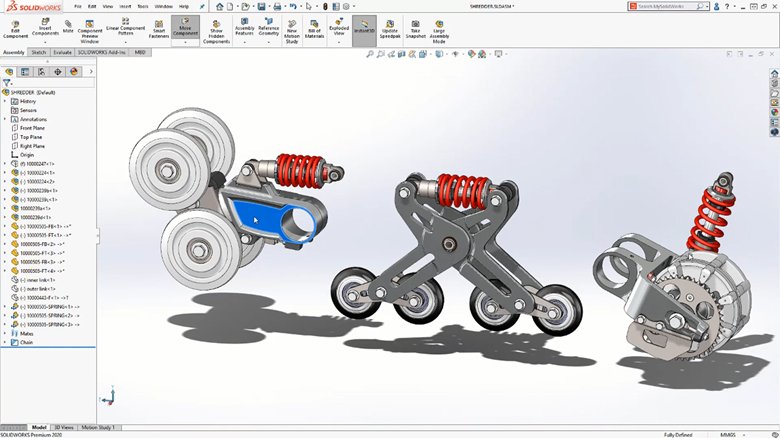

In her new role as VP of Engineering, Selma will spearhead all product development initiatives in alignment with the RISE™ product roadmap. Her primary focus will be on optimizing product performance and reliability while minimizing costs. This appointment comes at an opportune moment for RISE™ as the company continues to foster collaborative partnerships with industry giants such as Anthony Liftgates, Danfoss Power Solutions, and the USAF. Together, they aim to develop cutting-edge motion control solutions that enhance machine performance, promote environmental preservation, and enhance our overall quality of life. Selma's arrival is of utmost importance as RISE™ forges ahead with their collaborative efforts alongside Anthony Liftgates and the United States Air Force to revolutionize equipment for the forthcoming era of productivity.

Colin Angle, Chairman, Founder, and CEO of iRobot, Selma's former employer, spoke highly of her exceptional abilities, stating, "When I think of iRobot and what makes us special, I think of Selma. She has a drive and passion not just to solve the problem she was given but to find a solution for what we were trying to accomplish."

Selma herself expressed her enthusiasm for joining RISE™ Robotics, stating, "I firmly believe that sustainable growth necessitates innovation, assembling the right talent, establishing effective governance, fostering healthy workplace environments, and embracing flexibility. At RISE™ Robotics, I am eager to develop strategic plans that encapsulate these vital elements and yield tangible results."

The entire RISE™ Robotics community is encouraged to extend a warm welcome to Selma. Her expertise and enthusiasm are set to invigorate the team, and the company eagerly anticipates the positive impact of her leadership on their future endeavors.

As RISE™ Robotics continues to progress, subscribers are urged to stay tuned for further updates. RISE™ expresses heartfelt gratitude to the community for their unwavering support and involvement in their mission.